Choosing Weather-Resistant Front Door Materials for Heavy Rainfall in the North West

As a homeowner in the North West, where heavy rainfall is a common occurrence, it is important to consider weather-resistant front door materials to safeguard your home from the elements. When selecting a front door that can withstand the rainy climate of the North West, it is crucial to choose a material that offers both durability and aesthetic appeal. In this article, we will explore the best weather-resistant front door materials suitable for heavy rainfall in the North West region.

Fiberglass Doors

Fiberglass doors are an excellent choice for regions with heavy rainfall, including the North West. These doors are highly resistant to moisture and are less prone to warping, cracking, or rotting compared to wood doors. Fiberglass doors can be designed to emulate the look of wood, offering the beauty of a natural wood grain without the susceptibility to water damage. They also provide excellent insulation, helping to keep … Read the rest

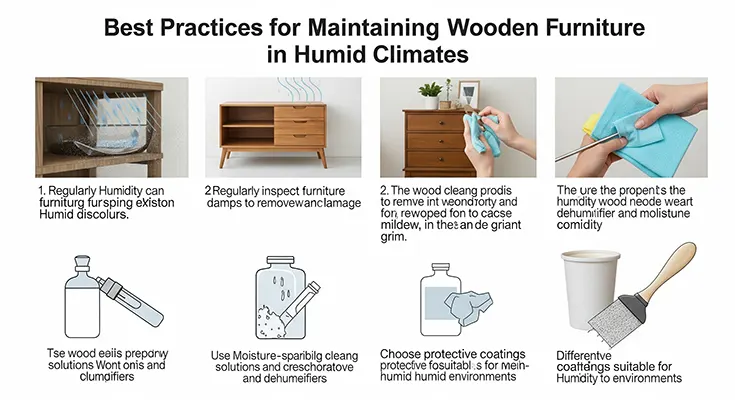

Best Practices for Maintaining Wooden Furniture in Humid Climates

Wooden furniture can bring warmth, beauty, and a touch of natural elegance to any space. However, in humid climates, the excess moisture in the air can pose challenges for the upkeep of wooden furniture. To preserve the luster and integrity of your wooden pieces, it’s important to implement best practices for maintenance in humid environments. By following these guidelines, you can safeguard your furniture against the potential damaging effects of high humidity, ensuring its longevity and enduring appeal.

1. Opt for Hardwood Furniture:

When selecting wooden furniture for a humid climate, consider opting for hardwood varieties such as teak, mahogany, or oak. Hardwoods are less prone to warping, swelling, or splitting in high humidity, making them better suited for such environments compared to softwoods. Additionally, hardwoods are naturally more resistant to moisture, minimizing the risk of damage due to fluctuating humidity levels.

2. Use a Dehumidifier:

In regions with consistently … Read the rest

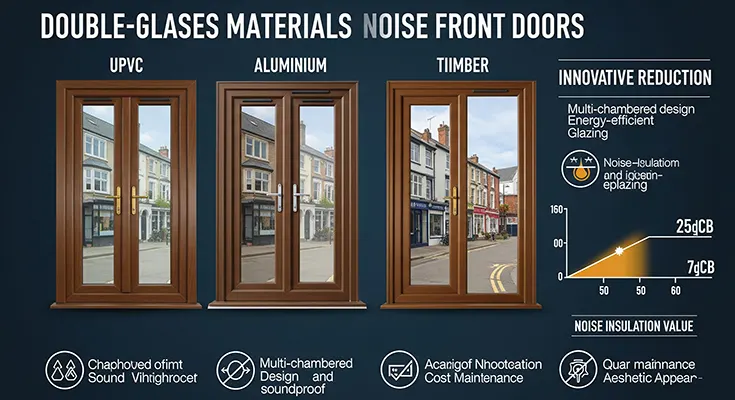

Choosing the Right Double Glazed Front Door Materials for Noise Reduction in Busy English Towns

Living in a bustling English town can come with its fair share of noise pollution, making it challenging to find peace and quiet within the confines of your home. One effective solution to minimize the impact of exterior noise is to invest in a double glazed front door. However, the material of the door can significantly impact its noise reduction capabilities. By selecting the right double glazed front door materials, homeowners can create a tranquil sanctuary within their homes, shielded from the urban clamor.

1. uPVC Double Glazed Front Doors:

uPVC (unplasticized polyvinyl chloride) front doors are a popular choice for homeowners seeking noise reduction in busy towns. The insulating properties of uPVC, combined with a double glazed configuration, provide an effective barrier against external noise. Additionally, uPVC doors are relatively low maintenance, durable, and can withstand the rigors of busy urban environments without warping, fading, or deteriorating.

2. Composite

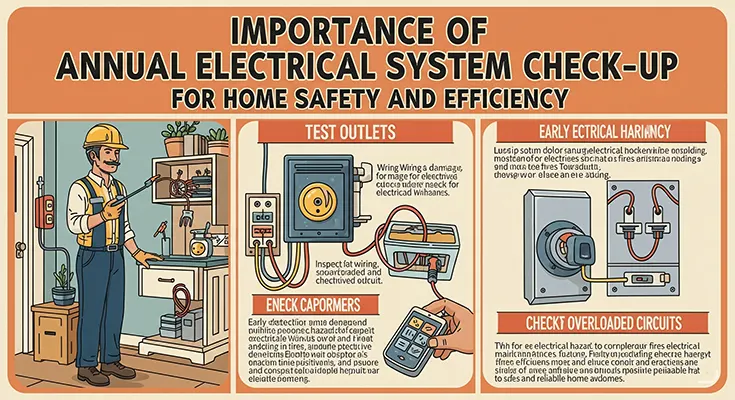

… Read the restImportance of Annual Electrical System Check-up for Home Safety and Efficiency

The electrical system is the backbone of any home, powering appliances, lighting, and essential devices that ensure comfort and convenience. However, many homeowners overlook the importance of regular maintenance of their electrical systems, which can pose serious safety hazards and impact energy efficiency. An annual electrical system check-up is crucial for ensuring the safety and efficiency of your home, minimizing the risk of electrical faults, fires, and costly energy wastage.

1. Safety Precaution Against Electrical Hazards

Electrical malfunctions are one of the leading causes of house fires, posing a significant risk to life and property. An annual electrical system check-up conducted by a qualified electrician can help identify potential hazards such as faulty wiring, overloaded circuits, or damaged outlets. By addressing these issues proactively, homeowners can prevent electrical fires and protect their families from harm, making safety the top priority in maintaining a well-functioning electrical system.

2. Detecting Early Signs

… Read the restExploring the Benefits of Low-Maintenance Fibreglass Front Doors for Coastal Areas in the UK

Living in a coastal area in the UK presents a unique set of challenges, especially when it comes to maintaining the exterior of your home. The harsh coastal climate, with its salt-laden air and frequent exposure to moisture, can take a toll on traditional front doors made of wood or metal. This is where low-maintenance fibreglass front doors come to the rescue, offering durability, aesthetics, and protection tailored to the specific needs of coastal properties.

1. Resilience to Harsh Coastal Conditions

Fibreglass front doors are well-suited to withstand the corrosive effects of saltwater and moisture prevalent in coastal areas in the UK. Unlike wood, which can warp or rot when exposed to high humidity and salt air, fibreglass is inherently resistant to these elements. This makes fibreglass doors an ideal choice for homeowners seeking a long-lasting solution that can withstand the coastal environment without compromising on aesthetics.